Innovation in Workboat Design

How Gilbert Associates Engineers the Next Generation of Workboats

Innovation looks different in the marine world. It doesn’t always arrive wrapped in sleek packaging or cutting-edge buzzwords. Sometimes, it’s welded in steel, hidden in the hull of a workboat that was designed not to impress — but to perform.

Workboat design is evolving rapidly, driven by environmental goals, digital modeling, and new propulsion technologies. At Gilbert Associates, innovation doesn’t mean reinventing the rudder. It means finding smarter ways to design a boat — to improve performance, safety, and sustainability without compromising reliability.

What Is a Workboat?

A workboat is any vessel designed to perform a job, not just transport people for pleasure. These are the tugboats that push barges up the river, the ferries that connect islands, and the tenders that serve offshore platforms. In short, if it moves people, cargo, or equipment for commercial purposes, it’s a workboat.

Gilbert Associates has designed everything from passenger ferries and towboats to commercial vessel designs for fishing and research. Each one demands a unique approach to boat hull design, propulsion, and balance.

Redefining Innovation in Workboat Design

Innovation in workboat design can take many forms — from propulsion to power management to accessibility. The firm’s engineers look for solutions that address the realities of modern maritime operations: stricter emissions standards, energy efficiency, and new onboard technologies.

Electric and Hybrid Propulsion

A prime example is the M/V Capt. Almer Dinsmore, a hybrid passenger vessel for the Maine State Ferry Service. Gilbert Associates adapted the vessel design to accommodate batteries and advanced electrical systems. This required enhanced fire protection, integrated control systems, and additional engineering for stability and safety.

The team also explored designs for a hybrid-electric river towboat, a concept particularly suited for “line boat” operations — short-haul towing where electric propulsion could offer significant fuel and emissions savings.

Dockside and Charging Innovations

As the industry experiments with electric ferries, the infrastructure to support them is evolving too. In San Francisco, for example, ferries now connect to a floating charging barge equipped with large-scale batteries. Designing vessels to interface with such systems requires flexibility and foresight — the ability to design a boat that can adapt to both fixed docks and mobile, floating chargers.

Safety in Battery Technology

Lithium-ion batteries are powerful but complex. The ASTM F3353-19 standard governs how marine engineers must protect these systems from fire. Gilbert Associates designs battery rooms that can withstand explosions and use high-pressure water mist systems to cool overheating cells.

These are some of the most dangerous systems to deal with, but every year the technology gets safer, lighter, better isolated, and more efficient.

Meeting Modern Industry Needs

Innovation doesn’t always come from technology alone — sometimes it’s about solving persistent, practical challenges in commercial vessel design.

Accessibility and Usability

Meeting ADA requirements on small passenger vessels can be difficult. Elevators and lifts are bulky, and adding accessible features to the main deck can affect layout and performance. Gilbert Associates integrates accessibility into vessel design in ways that preserve functionality, stability, and aesthetics.

Smarter Power Management

Upgrading older equipment is another area where innovation pays off. The M/V Delaware, for example, originally relied on mechanical governors to run its generators. Gilbert Associates refitted the vessel with modern electronic controls that allow generators to operate in parallel, improving electrical efficiency and reducing the need to shut down systems like HVAC when using bow thrusters. Such an HVAC refit will likely pay for itself through efficiency.

Technology in Modern Vessel Design

3D Modeling and Finite Element Analysis

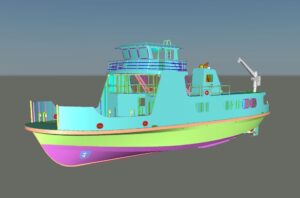

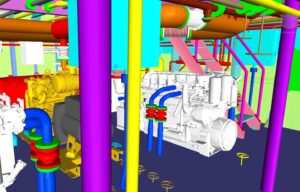

Digital tools have transformed the way naval architects design a boat. Gilbert Associates uses finite element analysis to verify structural strength in critical areas — such as crane bases — and collaborates with shipyards using full 3D modeling to identify interferences before construction.

Shipyards can now extract individual plates and piping spools directly from the model, cutting them with precision and assembling them like a puzzle. This makes the welders’ jobs more efficient — everything fits where it should.

The M/V Charles Norman Shay is a recent example where these digital tools played a key role in modeling, construction, and Coast Guard verification.

Navigating Regulations

The regulatory framework for commercial vessel design is often slow to change. For example, Subchapter H, setting the requirements for passenger vessels over 100 gross tons, was written in the 1970s for ocean-going ships far larger than most modern workboats. Although freight is not carried in the hold, the tonnage measuring system still has broad implications for the overall vessel design and outfit.

To accommodate the additional machinery required to support new propulsion technology, the tonnage restrictions of Subchapter K, which govern smaller passenger vessels, must be exceeded. This means that owners are often required to treat a vessel as ocean-going, even though it will never lose sight of shore and has ready access to emergency assistance.

The Future of Workboat Design

The next decade promises change. Containerized cargo on inland waterways, automation, and alternative fuels are all reshaping the conversation around innovative workboat design.

There’s even buzz around hydrofoils — vessels that “fly” on submerged wings to reduce drag and fuel use. While Gilbert Associates doesn’t design hydrofoils, the team studies these technologies to understand how they might influence future boat hull design and performance standards.

Ultimately, innovation in workboat design isn’t about novelty — it’s about necessity. The best designs solve real problems, making a vessel work better, safer, and longer.

To learn more about how Gilbert Associates can put our problem-solving experience to work on your next boat design, reach out to us today.